Kaeser M170 Mobilair perfect performance even in extreme conditions. Using the arrow keys, system pressure can be precisely adjusted in 0.1 bar increments on the SIGMA control mobile’s digital display.

This not only enhances flexibility but, in combination with the electronic inlet valve control, also achieves significant energy savings especially when operating in partial load.

-

Excellent accessibility

The M170’s user-friendly design not only ensures simple operation and outstanding manoeuvrability: The unit’s large enclosure doors also provide excellent component accessibility for unrivalled ease of service. Stationary systems are equipped as standard with maintenance connections for bleeding of engine oil and compressor fluid.

-

Ambient temperature

Standard units are rated for ambient temperatures between -10 and + 50°C. A version for lower ambient temperatures is also available.

-

Large capacity, transparent fuel tank

When fully filled, the tank carries sufficient fuel for an entire work shift without the need for refuelling. For ease of operation, an automatic shut-down feature is activated when the fuel level becomes too low. A pre-warning from the Sigma Control mobile provides additional peace of mind.

-

Simple to operate

The ability to switch over manually from idling to full load operation ensures a reliable, gentle startt when using the in cold ambient conditions.

The Sigma control mobile and intuitive operate the M170. Features also include automatic monitoring and shutdown and an optional cover flap to protect the control panel.

-

Oil temperature control

The M170 is automatically controlled thermostatic valve ensures that optimal operating temperature is reached the compressor’s fluid circulation loop from excessive condensate accumulation. This in turn significantly extends cooling fluid and separator cartridge service life and also enhances the unit’s long-term durability.

-

Cool and condensate-free

The compressed air is cooled to 7°C above ambient. Moreover, the angled design of the optional compressed air cooler facilitates condensate drainage and the hot exhaust gases from the engine are used to evaporate the condensate. This design condequently ensures reliable frost protection during the winter months.

-

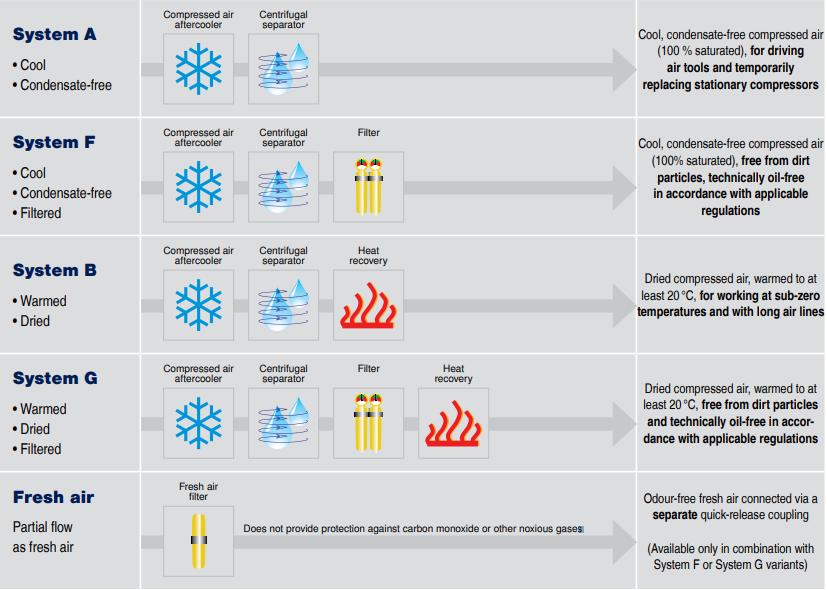

Compressed air treatment

Additional air treatment components need to be installed downstream from the aftercooler and centrifugal separator (e.g. filter combinations for concrete cleaning as per ZTV-ING) in order to achieve compressed air of a specified quality class. The differential pressure indicator enables filter status to be monitored quickly and easily.

-

Sigma control mobile

This advanced compressor controller ensures optimised compressed air availability and fuel efficiency using state-of-the-art electronic engine management. The system is both shock and vibration proof corresponding to IP 65 electrical protection. Features include mode display, user-friendly operation, system monitoring and diagnostics.

Kaeser – The world is our home

As one of the world’s largest manufacturers of rotary screw compressors, Kaeser kompressoren is represented throughout the world by a comprehensive network of branches, subsidiary companies and authorised partners in over 100 countries.

with innovative products and services, Kaeser Kompressoren’s experienced consultants and engineers help customets to enhance their competitive edge by working in close partnership to develop proressive system concepts that continuously push the boundaries of performance and compressed air efficiency. Moreover, the decades of knowledge and expertise from this industry-leading system provider are made available to each and every customer via the Kaeser group’s global computer network.

These advantages, coupled with Kaeser’s worldwide service organisation, ensure that all products operate at the peak of their performance at all times and provide maximum availability.

Please contact us at: 0833 486 586 for further to support!

Tiếng Việt

Tiếng Việt