Working principle of Air Compressor

The working principle of an air compressor – Kaeser air compressors are versatile and essential compressed air equipment for any factory, workshop, and construction site. The key advantage of an air compressor is its powerful operation. Maintenance is truly simple, requiring only regular oil checks, and various tools can be powered by a single motor using compressed air pressure to achieve maximum potential.

High flexibility, with equipment available in multiple sizes and pressures suitable for various applications. These include sandblasting, road breaking, and general tool use. Their extensive range of options allows customization to meet nearly any need. They are ideal units for home rentals, truck repairs, and urban applications.

Air compressors are a testament to human ingenuity. It is important to understand the working principle of an air compressor in order to choose the appropriate machine for one’s project.

Mục lục

Working principle of Air Compressor

An air compressor operates by compressing air into a storage tank to create pressure. Subsequently, the compressed air is forced through an opening in the tank, where pressure builds up. Think of this equipment like an open balloon: compressed air can be used as energy when it’s released.

They are powered by an energy-variable motor converted from electrical to kinetic energy. It’s akin to how an internal combustion engine operates, using a crankshaft, piston, valves, head, and connecting rod.

From there, the pressurized air can be harnessed to power various kinds of tools. Some common choices include nail guns, wrenches, impact drivers, sanders, and paint sprayers.

There are various types of air compressors, and each type has distinct characteristics. Generally, the differences are not too pronounced: all focus on how an air compressor handles the movement of air.

How Each Type of Air Compressor Works

There are two methods to achieve air compression: positive displacement and dynamic. Each method has several subcategories which we discuss below. The results are relatively similar, but the processes to achieve them are different.

Here are the working principles of positive displacement and dynamic air compressor:

Positive DisplacementPositive Displacement

A positive displacement air compressor will force air into a chamber with decreasing volume to compress the air.

Positive displacement is a term describing various air compressors that derive energy through the positive displacement of air. While the internal systems may differ, the method of energy delivery is the same.

Some types of positive displacement compressors are better suited for industrial workloads. Below are three main types of air compressors that utilize positive displacement:

Rotating screw

The working principle of a rotary screw air compressor

A rotary screw air compressor has two “screws” inside that rotate in opposite directions, trapping and compressing air between them. The two screws also create continuous motion as they rotate around.

This is a common type of air compressor and one of the easiest to maintain. The motors are often of industrial size and are excellent for continuous use.

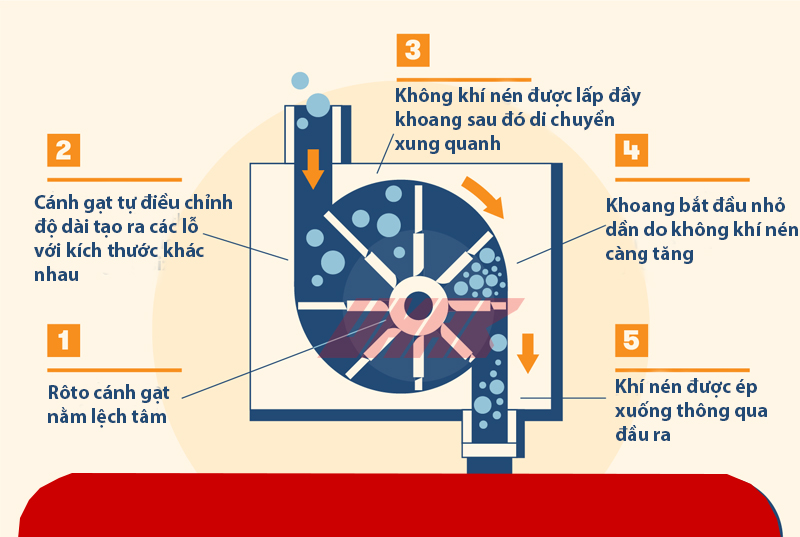

The working principle of a vane air compressor

The working principle of a rotary vane air compressor.

A rotary vane air compressor is similar to a rotary screw compressor, but instead of screws, vanes are mounted on a rotor and rotate within a chamber. Air is compressed between the vanes and its casing, and then pushed out through a separate exhaust port.

Vane compressors are very user-friendly and are thus quite popular for private projects.

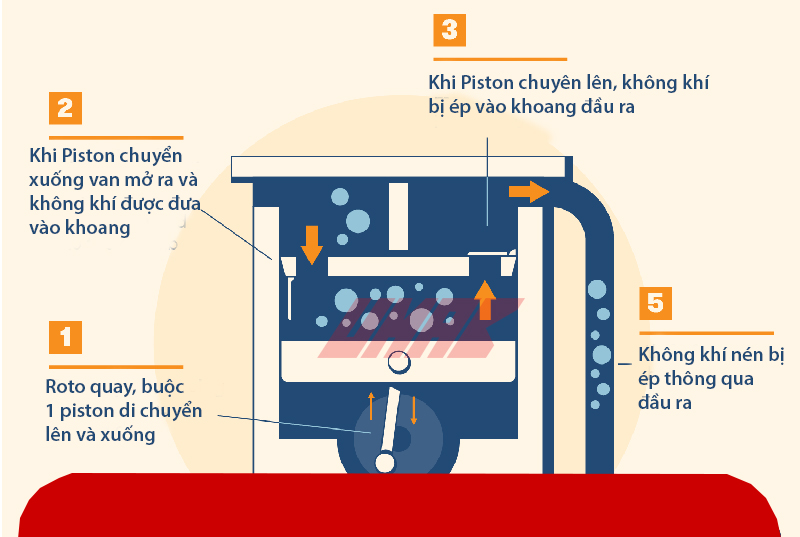

Piston Type

Reciprocating air compressors (also called reciprocating motion) use pistons driven by a crankshaft to deliver air at high pressure. They are often found at smaller sites and are not designed for continuous use.

There are two types of piston air compressors: single-stage and two-stage.

Single-Stage

In a single-stage compressor, air is compressed on one side of the piston, while the other side performs its function: as the piston moves downward, air is drawn in, and as it moves upward, air gets compressed.

Single-stage compressors are relatively affordable compared to other compressors and are usually easy to purchase; they can be found in most mechanical stores.

Two-Stage

A two-stage compressor has two compression chambers on either side of a piston. Two-stage compressors are often water-cooled with a continuous flow of water through the motor. This provides a more effective cooling system compared to other compressors.

Due to their higher cost, two-stage compressors are better suited for factories and workshops than for private projects.

Reciprocating Motion

A dynamic air compressor uses a rotating impeller powered by a motor to generate an airflow. The air is then constricted to create pressure, and kinetic energy is stored in the compressor.

They are primarily designed for large-scale projects, such as in chemical plants or steel manufacturing, so you might not find one at your local mechanic.

Similar to positive displacement compressors, there are two distinct types of dynamic motion: axial and centrifugal.

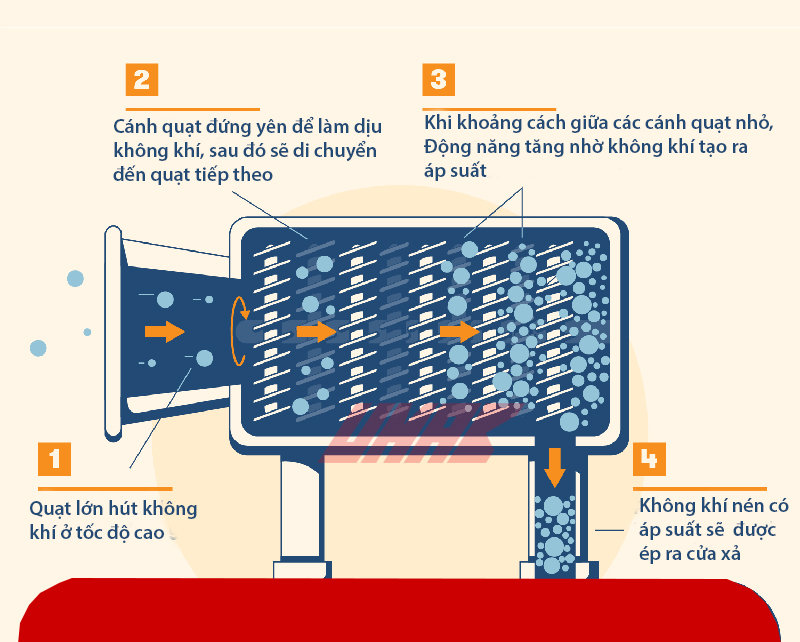

Axial Compressor

The working principle of an axial compressor involves a series of bladed rotors that generate air and force it through a small area. Although similar to other bladed types of air compressors, axial compressors operate with stationary blades that slow down the airflow, increasing pressure.

These types of air compressors are not very common and have limited functionality. They are primarily used in aircraft engines and large gas separation plants.

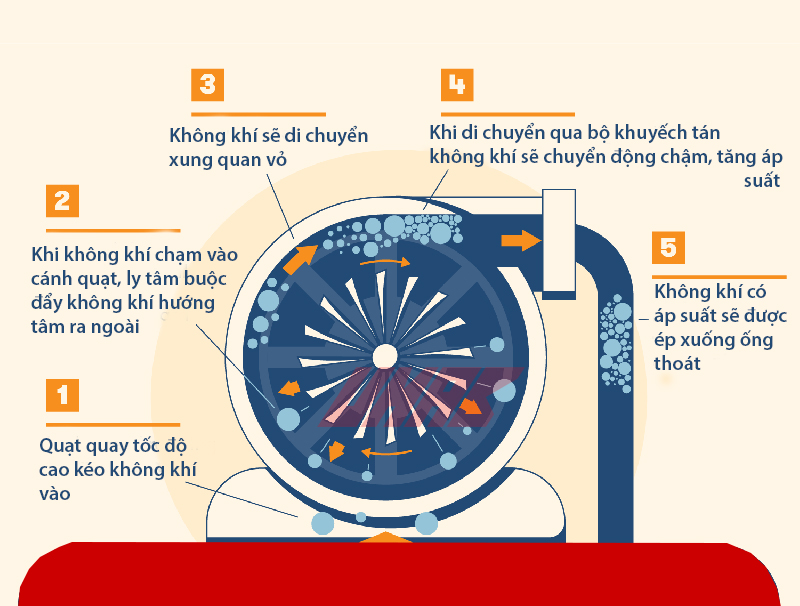

The working principle of a centrifugal air compressor

A centrifugal air compressor operates by drawing air into the center through a rotating impeller, then pushing it forward through centrifugal force or outward flow. By slowing down the airflow through a diffuser, more kinetic energy is generated.

High-speed electric motors are often used for these types of compressors. One of the more common applications of centrifugal compressors is in HVAC systems.

Above is an article about the working principle of air compressors. For all details about Kaeser air compressors, please contact the hotline at +84 833 486 586 or visit the website https://maynenkhikaeser.com.vn/ for further information!

Tiếng Việt

Tiếng Việt